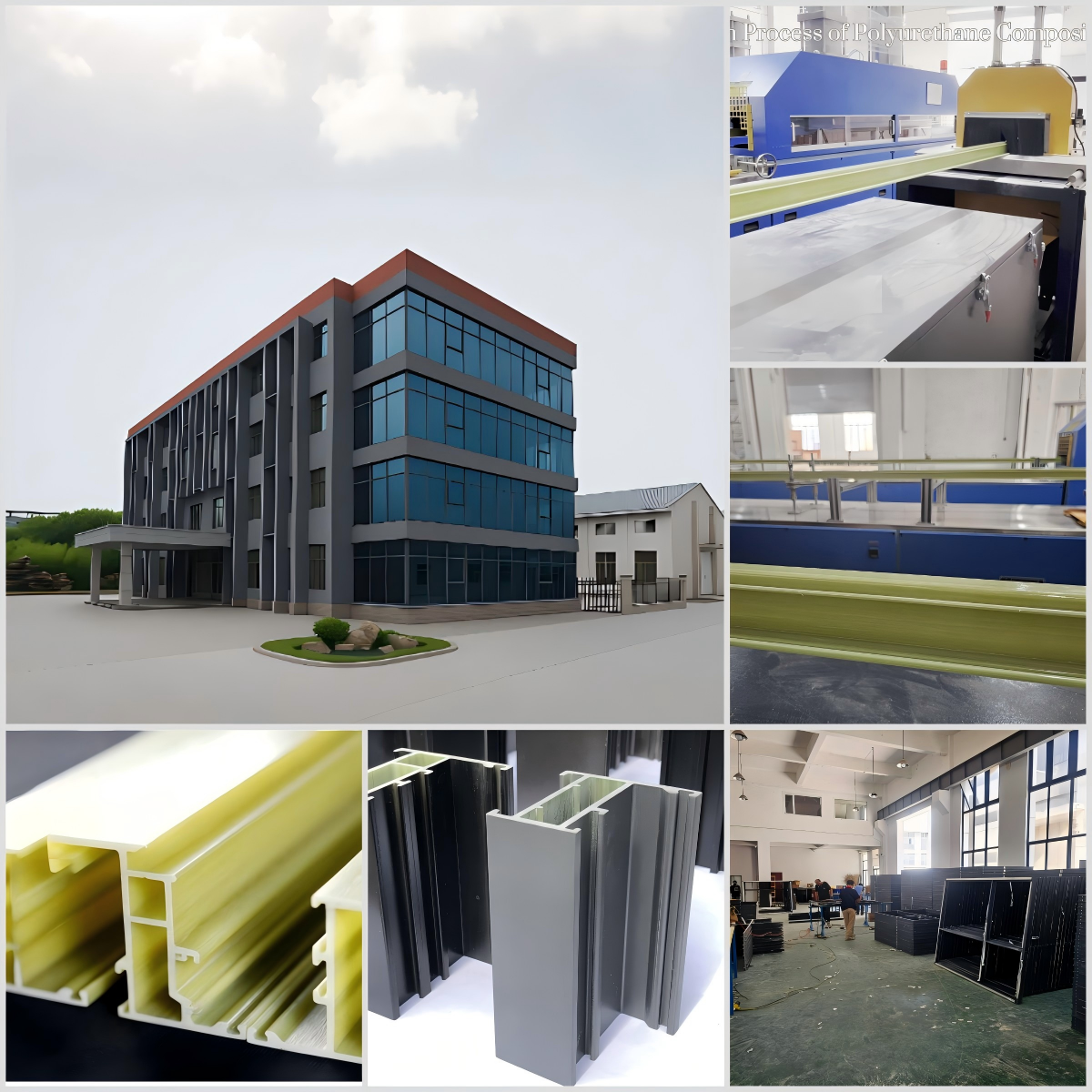

玻纤增强聚氨酯复合材料型材代加工服务(OEM)

爱乐居联手亨斯迈集团,共同推出具有划时代意义的高性能节能门窗材料——玻纤增强聚氨酯型材,将广泛用于航空航天领域的复合材料应用到了民用门窗系统,引领了新一代门窗材料的变革。

爱乐居凭借自身专业技术,自主研发了适用于聚氨酯复合材料复杂截面拉挤的注射盒、模具等一系列的设计、生产工艺,同时配合与亨斯迈集团共同研发的定制化拉挤用聚氨酯树脂,目前爱乐居的玻纤增强聚氨酯型材拉挤工艺能够实现长时间稳定生产,合格率达到95%以上,在世界范围内跻身于同行业先进水平。包括韩国LG等一众国际企业正在基于爱乐居现有设计、生产技术进行深度的交流与合作,以期能将此产品和相关技术引入本国市场。

公司自主研发的 140系列高性能推拉门窗系统,已经实现了耐火1小时、传热系数K值低至0.9 W/m²·K 的卓越性能,兼具安全与节能双重突破。

作为多家世界500强企业的OEM合作伙伴,爱乐居在汽车轻量化、新能源汽车阻燃解决方案、太阳能边框与支撑结构以及高性价比复合材料优化应用等领域均有卓越表现,致力于为全球客户提供创新、高强度、可持续的复合材料解决方案。

在全球减排的大背景下,世界各国均在提高门窗节能要求,玻纤增强聚氨酯门窗作为新型节能材料,在世界范围内也逐步获得了广泛认可,包括丹麦VELUX、德国Inoutic、美国Pella在内的一些知名窗企都有同类产品作为他们的高端产品系列推向市场。

聚氨酯拉挤产业,在我国基于健全的上下游产业链的优势,从原材料、设备制造、模具加工、涂装工艺、门窗制作到专业技术人员的培训等各方面较之欧美国家均有不小的优势。而目前在聚氨酯门窗拉挤行业内,爱乐居无论在产品系列完善度、产品品质的管控,还是大量产的数量方面均处于较为领先的地位。并已经与全球一些大型系统门窗品牌达成合作。

目前,爱乐居拥有全自动一体化门窗加工产线,熟练的聚氨酯门窗加工&组装团队,通过了ISO9001,ISO14001,ISO45001三体系认证,年产能达100万㎡门窗。

爱乐居致力于为全球各行业客户提供专业的玻纤增强聚氨酯复合材料拉挤型材代加工服务,为广大客户提供从产品截面优化、模具设计、到模具及型材生产等全套技术方案。

沪公网安备 31011502010343号

沪公网安备 31011502010343号